Bio Mixer development

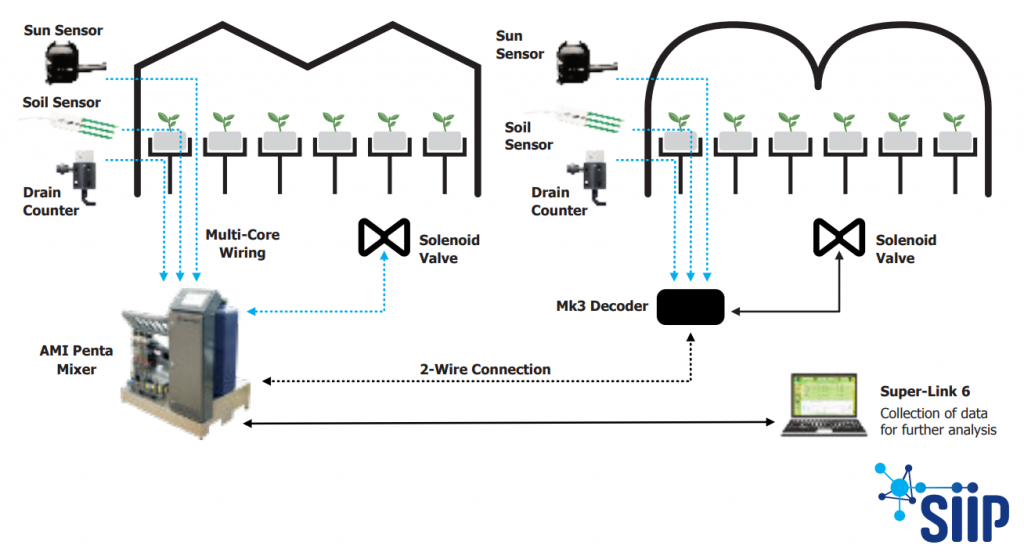

The product was developed in the beginning of this year and has now been tested for a few months. “ A lot of people have already shown interest and we’ve even already sold some.” The product was developed in cooperation with customers in Germany and Austria, who went to Senmatic’s local dealers with the question for a way to easily add biomass to their irrigation water. Together with the dealers, they worked it out.

“Growers want to add microorganisms or bio-fertilizers to the irrigation water, without changing the EC. Therefore, the dosage should be proportional to the amount of irrigation water and automatically controlled for each culture, via the fertilizer mixer. You can see and follow the EC on the bio mixer.”

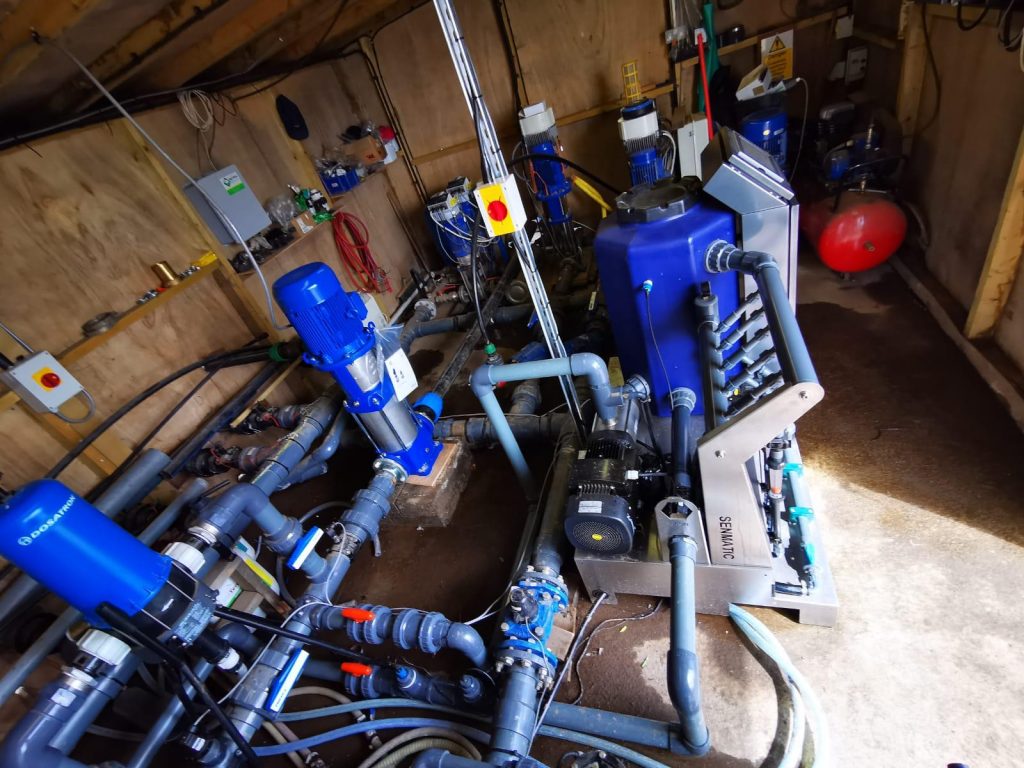

The Bio Venturi is a part added to the Bio Mixer. It is suitable for the adding and precise dosage of bio-fertilizers, nematodes, H2O2, Bactimos, beneficials and microorganisms. The Bio Mixer is suitable for all kinds of crops in greenhouses, indoor farms, as well as in outdoor, open field crops. Johnny Rasmussen, Business Development Manager with Senmatic: “We took the knowledge from the grower and our expertise and brought that together. Now we have the bio venturi.”

Helping the grower

The bio venturi, which is added to the AMI Penta Bio Mixer, saves the grower many labour hours. “When the grower wants a certain amount of organic matter on his tables or in his drippers, he has to add that organic matter by hand. That used to be work which took quite some time. Now, instead of doing it manually, it’s done by the computer which is more precise, so it saves money as well.”