Description

The AV-010 Air & Vacuum Valve discharges air at high flow rates during the filling of the system and admits air at high flow rates during drainage , pump shut-off or at water column separation.

Applications

Agricultural and landscape irrigation laterals.

Operation

The air & vacuum valve discharges air at high flow rates during the filling of the system and admits air at high flow rates during drainage, pump shut-off or at water column separation.

High velocity air will not blow the float shut. Water entry will lift the float which seals the valve.

The smooth discharge of air reduces pressure surges and other destructive phenomena.

At any time during system operation, should internal pressure of the system fall below atmospheric pressure, air will enter the system.

The intake of air in response to negative pressure protects the system from destructive vacuum conditions and prevents damage caused

by water column separation. Air entry is essential to efficiently drain the system.

As the system starts to fill, the valve functions according to the following stages:

- Entrapped air is released by the valve.

- Water enters the valve, lifting the float and sealing the valve.

When internal pressure falls below atmospheric pressure (negative pressure):

The float will immediately drop down, opening the air & vacuum orifice.

Air will enter the system.

Agriculture

![]() Main Features

Main Features

- Working pressure range: 0.2 – 10 bar

- Testing pressure: 16 bar

- Working Temperature : 600 C

- Maximum intermittent temperature : 900 C

- The body is made of high strength composite materials, and all operating parts are made of specially selected corrosion-resistant materials.

- Drip-tight sealing at low pressure.

- All parts are UV protected.

- Lightweight, small dimensions, simple and reliable structure.

Valve Selection

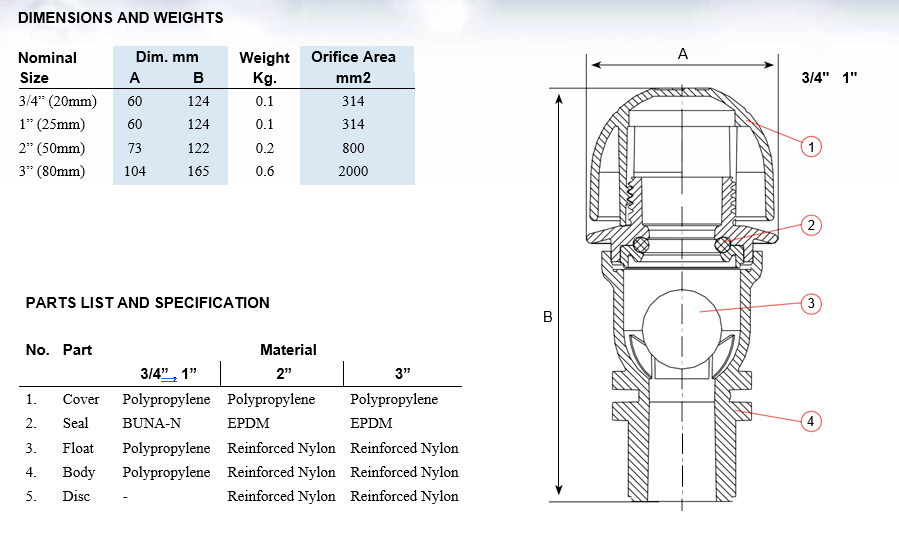

- Available in 3/4” (20mm), 2” (50mm)